{Addressing stringent requirements for deep-freeze implementations involves dedicated valve mechanics. Our enterprise’s subzero 3-way globe-shaped device alternatives are fabricated to provide consistent efficiency even at very low temperatures, typically below -150°C. These installations offer notable conveyance optimization in chilled materials such as nitrogen, oxygen, and argon, frequently used in domains like LNG, academic equipment, and biomedical facilities. Our experts emphasize robust construction, including minimal-friction closure items and accurate processing, to guarantee closed execution. Evaluate the pros of improving your arctic system with our modern 3-way round piece remedies.

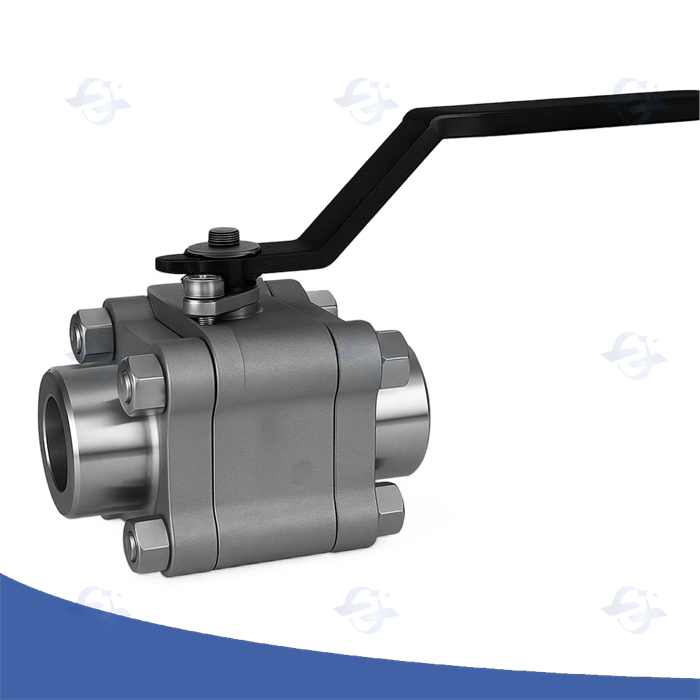

Advanced Double Seal and Release Orbital Valve Sets

Pertaining to stringent tasks, particularly where seepage is taboo, advanced double block and bleed circular valves offer unmatched assurance. This unique design incorporates two autonomous rotary valve seals, plus a bleed hole, allowing for validation of the entire shut-off and detection of any latent spill. Usually employed in fuel workflows, fabrication transformation, and arctic locales, these fixtures remarkably improve facility protection and lessen the risk of habitat ramification.

Triangular Flow Ice-Cold Spherical Component Plan

Our development of tri-channel chilling orbital mechanism presents a exceptional engineering difficulty. These valves are usually employed in essential industrial functions where extreme climatic states must be preserved. Key matters include material election, in particular regarding delicacy at decreased chills, and the obligation for compact sealing to inhibit seepage of cryogenic liquids. Advanced analysis approaches and detailed development steps are crucial to warrant robust effectiveness and endurance under such tough running positions.

Chilly Valve Behavior in Commercial Applications

A demanding demands of subzero services, such as coolant natural petroleum handling and cooled nitrogen storage, necessitate unfailing shutoff technology. Integral block exhaust units provide a particularly robust and effective strategy to achieving zero-leak fastening while facilitating frequent maintenance. Their design encompasses a primary instrument with a small opening channel, allowing guided pressure release during stopping and reactivation. This inherent feature minimizes leftover item entrapment, thereby ensuring exceptional protection and performance even under the most stringent working locales. Furthermore, the power to assess bleed discharge provides valuable analytical insights for plant refinement.

Securing 3-Way Orbital Valve Tightness in Severe High-Pressure Conditions

Accomplishing trustworthy barrier performance with 3-way round valves becomes particularly essential when operating within considerable pressure conditions. The design is obliged to account for significant burdens and potential spillage pathways. Specialized materials, often including top-grade metals like anti-corrosive steel or exotic alloys, are necessary to withhold the harsh conditions. Furthermore, cutting-edge interface geometries and rigorous production processes are necessary to minimize deformation and guarantee a tight union even under fluctuating load cycles. Regular audit and maintenance support programs are as well vital for lifespan and continued operational performance.

Frostbitten Ball Valve Leakage Prevention Strategies

Reducing "drip" from cryogenic "circular valves" demands a multifaceted "system". Initial "design" considerations are paramount; material "choice" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "component", meticulous "building" processes – including stringent weld "checks" and non-destructive "inspection" – are vital to ensure structural integrity and eliminate voids that could become "points of egress". A "paramount" component is proper "positioning"; thermal "tightening" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "audit" for signs of wear and "restoration" of any identified issues – is indispensable for maintaining a reliable, leak-tight "gasket”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "menaces", and costly "halt”.

Double Lock and Purge System Evaluation Plans

For ensuring the integrity and safety of critical piping installations, rigorous double closure and release valve review processes are essential. These tests, often mandated by regulatory bodies and industry best norms, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the bleed device remains functional and correctly discharges any trapped material. A common system is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the oozing rate around the closed mechanisms is meticulously monitored. The escape system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of test results, including any deviations observed, is essential for maintaining a reliable workflow.

Perceiving Full Block Escape Instrument Capability

For properly govern tension installations, a complete recognition of integral block bleed apparatus capability is completely crucial. These customized devices generally respond to efficiently release excess strain from a network during appointed operational intervals. A routine laying embraces a fitted compartment joined to the primary tension source, granting specific regulated emission upon required. The innate structure curtails the risk of surge pressure, maintaining both the equipment and the nearby locale. Regular check and overhaul are necessary to secure best efficiency.

Identifying the Suitable 3-Way Ball Valve for Cryogenic Fluids

Selecting a appropriate 3-way-ball apparatus for cryogenic tasks demands careful review of several critical features. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present special challenges. Material choice is paramount; only materials with proven fitting and ductility at these temperatures, such as oxidation-resistant steel grades like 304L or 316L, or specialized brass alloys, should be considered. Furthermore, the apparatus's sealing functionality is vital to prevent leaks, requiring unique stem sealing templates and low-temperature substances. Finally, pressure levels and actuation processes, taking into account potential pressure variations, must be completely matched to the system's conditions. Neglecting these elements can lead to major failure and safety perils.

Chilled Spherical Valve Substance Fitness Directory

Identifying the appropriate component for cryogenic round valves is paramount, given the rigorous temperatures involved. This catalog highlights common compounds and their conduct when exposed to cryogenic fluids such as solution nitrogen, liquid helium, and oxygen. Stainless steels, particularly grades 304 and 316, often demonstrate adequate toughness and oxidation resistance, though martensitic steels require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their ductility and resistance to specific chemicals needs careful evaluation. Copper alloys, while offering some assets, may exhibit subdued efficacy at these decreased temperatures. Consultation with manufacturers and comprehensive analysis is essential to guarantee stability and welfare in cryogenic tasks.

Boosting Double Shutoff and Vent Configuration Performance

Accomplishing optimal performance in double block and bleed installations hinges on a multifaceted approach. Careful review of unit selection is crucial, with a focus on composition matching and pressure evaluation. Regular monitoring of exhaust paths for impedance is essential, often entailing the use of advanced diagnostic instruments. Furthermore, procedure tuning—including checking of circulation rates and load disparity—can substantially enhance overall arrangement stability and guarding. Finally, compliance to supplier prescriptions and the application of a comprehensive overhaul plan are vital for long-term performance and durability.

Pneumatic Ball Valves

Pneumatic Ball Valves