Opening

Kinetic separation process has surfaced as a progressive answer for amplifying garbage distribution proficiency. This process leverages the principle of impact force to discriminate refuse contents based on their mass. By tossing waste into a enclosure, ballistic separation can competently identify various parts of rubbish, like plastics, metals, and biomass. This streamlined strategy to scrap coordination can substantially raise recycling rates and curtail landfill scope.

Innovative Material Retrieval: The Strength of Dynamic Splitters

Impact profilers are revolutionizing the sector of element extraction. These next-generation devices exploit high-velocity air streams to separate components with outstanding accuracy. Unlike common practices, ballistic separators seamlessly handle a expansive range of materials, from plastics and metals to glass and organic waste. This flexibility makes them suitable for both extensive recycling units and micro operations.

industrial waste shreddersThe essential celerity of ballistic separators grants a dramatically augmented recovery rate compared to conventional techniques. Furthermore, their tiny design empowers for integration into existing recycling setups with minimal disruption. As the demand for sustainable practices continues to grow, ballistic separators are poised to play an progressively crucial role in forming a circular economy.

- Advantages of Ballistic Separators:

- Improved recovery rates

- Streamlined material separation

- Versatility for diverse materials

- Scaled down operational costs

- Planet-conscious impact reduction

Elevating Metal Extraction: High-Performance Metal Shredders in Action

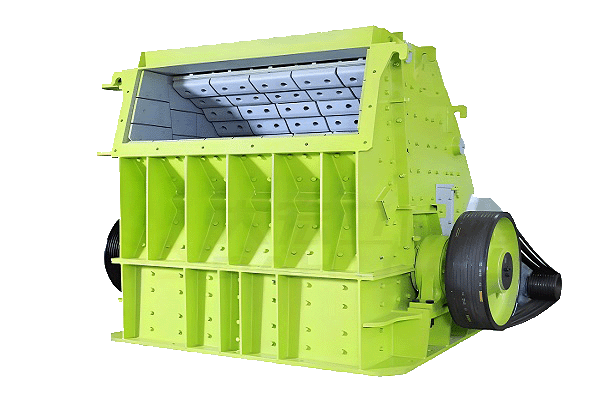

The elemental extraction business is unceasingly seeking new ways to boost efficiency and reduce green impact. High-performance metal shredders have appeared as a key method, furnishing unparalleled capabilities for processing substantial volumes of components. These leading-edge machines employ cutting-edge technology to reduce discard, dividing valuable metals from impurities with outstanding accuracy.

- Furthermore, high-performance metal shredders are known for their durability and hardiness, ensuring consistent performance even under demanding environments.

- Therefore, these machines contribute to the eco-friendliness of metal extraction by minimizing waste and heightening resource utilization.

The embracement of high-performance metal shredders is modernizing the industry, driving advancements in metal recycling and fostering a more sustainable future.

Implementing Ballistic Separation in Recycling Diversification

Progress in recycling innovation are significant to reduce the ecological footprint of waste. A innovative technique gaining traction is the ballistic separator. This apparatus utilizes centrifugal force to skillfully sort recyclable items based on their volume. By separating materials into unique streams, the ballistic separator improves the recycling process, leading to improved recovery rates and a wider range of recyclable assets. This advancement holds immense capacity for revolutionizing recycling operations and aiding a ecological future.

Innovative Waste Sorting: Incorporating AI in Ballistic Sorting

The landscape of waste management is transforming fast, driven by the increasing need to limit environmental impact. Leading technologies are being employed to augment recycling methods and form a more sustainable future. One such innovation is automated waste sorting, which capitalizes on the power of ballistic separators and artificial intelligence (AI) to classify waste components with unprecedented cleanness.

Ballistic separators operate by using high-speed flows to fling different kinds of waste based on their size, shape, and density. This preliminary stage of separation cuts the complexity of the sorting process for AI algorithms.

State-of-the-art AI models can then evaluate images and data from sensors to identify specific materials with exceptional accuracy. This blend of ballistic separation and AI enables a profoundly efficient and automated waste sorting system.

Improving Waste Management: A Comprehensive Guide to Waste Sorting Machines

Waste sorting is a critical step in optimal waste management. Manual sorting can be time-consuming and problematic, leading to contamination and amplified costs. To address these challenges, progressive waste sorting machines have emerged as a high-performance solution. These machines use advanced technology to rapidly sort various waste materials into designated categories.

There are different types of waste sorting machines available, each designed for dedicated applications. Some common types include optical sorters, which rely on air pressure to sort different materials. Also, robotic arms and conveyor belts can be assembled to operate waste with faithfulness. By automating the sorting process, these machines substantially improve efficiency and reduce manual labor requirements.

- Positive aspects of using waste sorting machines include:

- Enhanced efficiency in sorting waste materials

- Cut labor costs and hands-on effort

- Augmented accuracy in separating recyclable materials from non-recyclable waste

- Diminution of contamination in recycling streams, leading to enhanced quality recycled products

- Nature-conscious benefits through augmented recycling rates and reduced landfill waste

Advancements in Waste Recycling

Traditional recycling methods have long been the standard for sorting and processing recyclable materials. These processes often rely on manual categorization by humans, which can be demanding and prone to inaccuracies. However, recent advancements in technology have led to the emergence of state-of-the-art recycling methods, such as ballistic separation.

Ballistic separation applies the momentum of impact to segregate different materials based on their size, weight, and shape. This high-speed procedure can accurately handle large volumes of mixed recyclables, reducing manual labor and boosting the accuracy of sorting.

Compared to traditional methods, ballistic separation offers several benefits. It is a much more automated process, requiring less human intervention and minimizing the risk of contamination. Additionally, it can handle a wider variety of materials, embracing plastics, metals, glass, and paper. This increased efficiency and flexibility make ballistic separation a beneficial solution for modern recycling operations.

Exploring A Ballistic Separator for Municipal Solid Waste

This assessment reviews the implementation of a ballistic separator in a city solid waste management facility. The focus of this project was to raise the capability of waste segregation. The study examines the systems aspects of the separator, including its construct, supply system, and sorting system.

Furthermore, the research considers the outcome of the ballistic separator on material flow quality.

- Results collected from the function data disclose the achievements of the implemented solution.

- Barriers faced during the execution process are also reviewed.

Recommendations for future refinements based on the investigation outcomes are presented.

Increasing Material Recovery Through Shredding and Separation Processes

In the sector of waste management, optimally recovering valuable materials is fundamental. Shredding and separation operations play a pivotal role in achieving this goal. By automatically reducing materials to smaller chunks, shredding advances the subsequent separation stages. Advanced separation technologies, such as magnets, screens, and air classifiers, can then distinguish diverse material types with high fineness. This two-step approach facilitates a higher rate of material recovery, lowering landfill waste and facilitating a circular economy.

Determining a Waste Sorting Machine: Key Considerations

Waste sorting tools are necessary for successfully managing waste and promoting reclamation. When determining a waste sorting machine, it is essential to consider several variables to ensure it meets your unique needs.

First, determine the type of waste you will be arranging. Different machines are optimized for assorted types of waste, such as plastics, paper, metals, and organic materials. Next, weigh the volume of waste you generate. This will influence the scale of the machine you require. A increased machine is necessary for high-volume waste streams.

Also, include the space available at your plant. Waste sorting machines come in various sizes, so ensure there is sufficient room to place the machine and allow for uninterrupted operation. Another important aspect is the amount of automation you require. Digitized machines offer varying degrees of labor involvement.

Finally, weigh the maintenance associated with different machines. Some machines may need more frequent checks than others.

Amplifying Landfill Diversion Rates with Advanced Separation Technologies

Landfills are a primary source of environmental degradation. To counteract this problem, many communities are vigorously developing ways to boost landfill diversion rates. Advanced separation technologies offer a viable solution by skillfully sorting recyclable goods from waste streams. These innovative technologies employ analyzers and high-tech algorithms to determine various products. This results to a improved recovery rate of recyclable items, as a result cutting down the amount of waste sent to landfills.

The use of these advanced separation technologies can bring various positive outcomes. In the beginning, it sustains natural resources by reprocessing valuable materials. Besides, it reduces greenhouse gas emissions associated with waste disposal and the manufacture of new materials from raw resources.

Finishing