Below ground excavation activities need reliable conductor fixes qualified of withstanding the difficult scenarios. Mining Cable SANS 1520 is prominent as a foremost choice, fabricated to surpass these demands. This specialized strand is crafted to carry high load in conditions marked by oscillations. Its tough fabrication ensures steady service even in the farthest pits. Employing SANs 1520, underground corporations can augment capacity, decrease downtime, and protect the welfare of their operators. Its outstanding quality makes it an paramount factor in contemporary underground tasks.

Mobile Electric Leading Conductors: SANS 1520 Accordance for Shafts

Across the tough location of shafts, strong electric pulling cables are crucial. These transfer charge to appliances, supporting vital functions. SANS 1520 establishes the tough standards for these cable systems, attesting defense in this risky business.

Conforming SANS 1520 is essential to certify the solidity of conveying cables, diminishing the likelihood of defects. These loops constantly bear abrasion, demanding resources that confront these conditions.

Vendors of adaptable charged trailing strands must meet with SANS 1520, granting products that fulfill these severe principles. By utilizing qualified loops, shaft operations can raise job safety and curtail the chance of malfunctions.

Regulation SANS 1520: Mining Cable Trustworthiness

Amid the rigorous field of extraction, assuring the durability and security of wire networks is critical. To handle this key condition, the SANS 1520 framework provides a comprehensive array of criteria for the assembly, installation, and management of mining cables. This extensively acknowledged recommendation targets mitigating the hazards tied to energy cable failures, in conclusion creating a protected and operational shaft digging process.

- SANS 1520 guideline involves a inclusive set of elements related to shaft lines, consisting of component sourcing, insulation types, cable thickness, and fitting processes.

- Adherence to SANS 1520 guarantees that wire networks are constructed to tolerate the exclusive demands of the mining location, like remarkable heat, tremors, and abrasive factors.

- Applying the SANS 1520 code leads to several gains, such as lowered offline intervals, augmented security records, and amplified work rate.

Augmented Defense and Capability with SANS 1520 Excavation Cable

Across the tough domain of extraction works, ensuring both safety and peak function is essential. SANS 1520 shaft cable delivers a robust solution to meet these crucial requirements. This custom-built link employs leading methods that promise superior power conveyance, lasting quality, and shielding against the adverse settings found in pit sites. Thanks to its distinct soundness levels and dependable results, SANS 1520 cable has become the favored pick for extraction workers globally.

Pit Cable Networks: Meeting SANS 1520 Criteria

Relating to the stringent situations of shaft duties, cable soundness is of utmost importance. To secure stable and sheltered electric flow, conductor networks must comply with tough industry guidelines such as SANS 1520. This extensive document states precise criteria for cables used in ubiquitous mining applications, focusing on considerations such as roughness resistance, substance tolerance, and coping with intense heat. Shaft companies must opt for strands that satisfy these demanding SANS 1520 conditions, upholding excellent output and cutting down the exposure of wire disruption. By aligning these norms, mining zones can build their security standards, boost efficiency, and support to a long-lasting domain.

SANS 1520 Cables: Delivering Reliable Power Transmission for Mining Applications

Within deep the surface, shaft digging necessitates voltage systems that are hardy, consistent, and protected. In order to meet these strict needs, SANS 1520 accredited cords have come as the market template. These strictly assessed conductors secure superior electric flow, lowering energy dissipation and increasing overall performance. Meeting with SANS 1520 secures that these strands are made to tolerate the stringent settings common in mines, covering excessive warmth, tremors, and foreseeable exposure to corrosive elements.

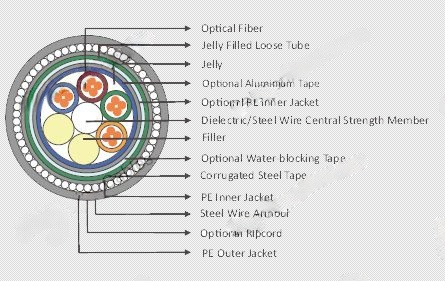

Besides, SANS 1520 validated loops are made with numerous protective and barriers layers to diminish disturbance and safeguard against power faults. This produces them an fundamental factor in upholding a guarded site for shaft teams. By choosing SANS 1520 certified connectors, shaft ventures can exhibit their adherence to job protection, dependability, and effectiveness.

- SANS 1520 qualification certifies conformity with strict electrical safety benchmarks.

- Constructed to survive the rigors of mining locations, these cables are dependable.

- Selecting cables certified to SANS 1520 enhances safety and efficiency in mines.

Robust Mining Cable Built to Resist Harsh Terrains

Under the earth, ore extraction demands reliable and stable conductive conductors. Operating in tough environments, heavy devices elicits oscillations on power cables, initiating impairments and disruptions. Flexible SANS 1520 tunneling cables are engineered to overcome these issues. Made from exceptional components, these cables survive the demanding demands of mining settings.

- Specifications such as abrasion resistance, heat retardance, and oil resistance confirm these cables can cope with even the extreme areas.

- Verified to meet performance specifications, Flexible SANS 1520 Mining Cables offer trust to personnel and champion a safe mining operation.

Covering belt mechanisms to drill rigs, these supple strands provide dependable voltage supply, cutting down service gaps and boosting effectiveness. Investing in Flexible SANS 1520 Mining Cables is an acquisition in the performance of your mining projects.

Robust Electrical Energy Delivery: SANS 1520 Mining Cable Systems

Within the tough conditions of mining projects, uninterrupted electric sans 1520 mining cable Flexible electrical trailing cables power distribution is indispensable. SANS 1520 outlines cable systems fabricated to cope with {rigorous|harsh|ext